Product marking has established itself as a key tool for optimizing efficiency, traceability and control within the supply chain. From the entry of raw materials to the exit of finished products, a well-implemented coding system reduces errors, improves traceability and allows a faster response to any logistical incident.

That’s why in today’s article, from United Barcode Systems, manufacturers of labeling, coding and marking equipment with more than 30 years of experience helping and advising companies by offering customized solutions, we tell you everything you need to know about product marking and its impact on the supply chain.

Why is product marking important in the supply chain?

The role of product marking in traceability

Product marking allows a unique identifier to be assigned to each unit, batch or pallet, ensuring complete traceability in real time. Thanks to direct printing or automatic labeling systems, companies can accurately record and trace the path of each product from its origin to its final destination. This traceability not only improves inventory visibility, but also facilitates the detection of incidents or the management of product recalls, if necessary.

In turn, a reliable coding system significantly reduces the risk of losing critical information. Barcodes, DataMatrix or QR codes printed directly on secondary packaging or labels ensure automated reading of key data at every stage of the supply chain, even in demanding operational environments or harsh environmental conditions.

In the food and bakery industry, for example, coding systems have to cope with factors such as high temperatures, presence of flours, oils and dust. Products are often packaged in bags, trays or porous boxes that must be legibly and durably identified throughout the entire process, from the oven to the point of sale. Here, the printing must remain intact even after multiple manipulations and thermal changes.

In the beverage industry, where humid environments and surfaces with condensation predominate, codes are applied on shrink-wrapped packs, cartons or even plastic film. It is crucial that the marking does not deteriorate with humidity or during transport, ensuring reliable reading in automated logistics centers and during mass scanning in warehouses.

For cold production lines, such as frozen or refrigerated products, the challenge lies in the adhesion of the ink or labels on surfaces such as polystyrene trays, plastic bags or shrink-wrap packaging. The marking must withstand low temperatures, permanent humidity and rapid cooling processes, without compromising the quality and legibility of the code.

There are also other industries with extreme conditions, such as the building materials sector, where dust in suspension can affect print quality, or the cleaning products and chemicals sector, which requires inks that are resistant to corrosive agents. In these cases, the print must resist contact with aggressive compounds, friction or impacts during transport, while maintaining the integrity of the data.

Guaranteed solutions for demanding environments

At United Barcode Systems, our APLINK equipment is specially designed to deliver high performance even in the most demanding conditions. For example, the APLINK HRX has the ability to print directly onto secondary packaging such as boxes, trays, sacks or shrink packs, ensuring accurate, durable and 100% readable printing, regardless of the type of surface or operating environment.

The APLINK HRX are high resolution inkjet printers designed to offer maximum performance and accuracy in coding, both on porous and non-porous surfaces. Thanks to its new grayscale print head, it allows to adjust up to 7 drop levels in the GS10 model and 3 in the GS05, achieving superior contrast and exceptional definition in each print.

Their speed of up to 250 m/min and a cadence of 30 prints per second make them an ideal solution for high-demand environments, ensuring efficiency without compromising quality. In addition, its CPE (Contrast Per Element) technology makes it possible to regulate contrast by zones, optimizing ink consumption and highlighting the most important elements of the message.

It incorporates functionalities such as the FIX (Flex Integration System), which allows the head to rotate on three axes to print in lateral, upper or inclined position, adapting easily to any line configuration. It is also compatible with UVLED curing systems, ensuring immediate ink curing even on more complex materials. Its 7“ or 10” HMI controller can be independently positioned for more flexible and convenient management. In addition, thanks to its bottle auto-detection system, it avoids ink change errors, ensuring reliable and continuous marking.

How tagging facilitates inventory management

The use of tagging makes it possible to automate processes such as counting, sorting and tracking of goods within the warehouse. This contributes to having an accurate and up-to-date view of stock, minimizing inventory errors and improving decision making in logistics management.

Having coded information readable by scanning systems speeds up the location of products, which reduces search and order preparation times. This translates into increased productivity and operational efficiency, especially in environments with a high volume of SKUs or multiple storage locations.

Improved speed and accuracy of logistics processes

Optimization of product reception and dispatch

At incoming and outgoing goods points, marking allows instant validation of incoming or dispatched products. Whether through fixed or mobile readers, logistics personnel can verify the contents of each unit without having to open the packaging, which speeds up the operation without sacrificing control.

This is especially relevant in companies with high product turnover, where every second counts. Automatic identification by means of printed codes or labels applied in real time allows a smoother synchronization with management systems, thus avoiding possible bottlenecks.

Reduced human error and improved information accuracy

Manual identification and registration processes are one of the main sources of error in the logistics chain. By replacing these procedures with automated marking, the risk of errors in printing or labeling, documentation or product location is minimized.

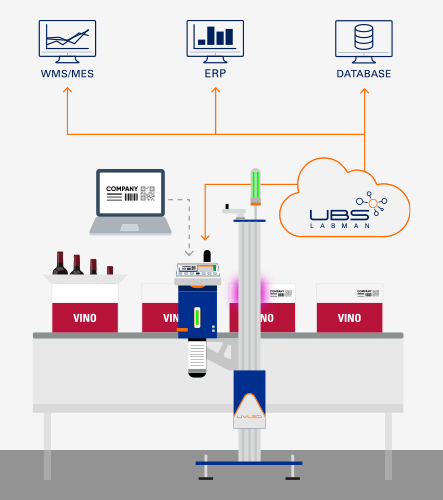

The result is better quality information available to ERP, WMS or MES systems, which reinforces consistency between physical and digital operations.

This not only improves the efficiency of the logistics flow, but also strengthens document traceability and responsiveness to audits or inspections.

Advantages of product marking automation

Integration with enterprise software and management systems

One of the great benefits of automated marking is its ability to integrate with business management solutions. Modern printing and labeling equipment can communicate directly with ERP, MES or WMS systems thanks to software such as UBS LABMAN, allowing data to flow seamlessly between the production line and the digital environment.

Benefits of automated coding on operational efficiency

Automated marking allows you to maintain a constant flow of production without unnecessary downtime. When configured to print in real time on cases, bags or pallets or others, the systems reduce changeover time and tailor the message to each product without the need for manual adjustments.

Reduced operating costs through product marking

Savings in labor and resources

Automated marking significantly reduces human intervention, optimizing operating times and minimizing the need for constant supervision. By eliminating repetitive manual tasks, costs associated with human error, adjustment breaks and downtime are reduced.

Reduced risk of losses and errors

The use of accurate and reliable marking systems reduces incidences of misidentified products, incorrect or illegible labels, avoiding returns, regulatory penalties or losses due to rework. Consistent coding ensures traceability at every stage and provides real-time control over product location and status.

Regulatory compliance and improved supply chain security

How marking contributes to international regulatory compliance

Contemporary marking systems, such as those from United Barcode Systems, allow you to include all the information required by regulations such as GS1, REACH, CLP or Regulation 1169/2011, among others. Incorporating legible codes, batches, expiration dates, composition or traceability ensures that the product can move smoothly across international borders and logistics channels.

Ensuring product quality and safety

Correct identification throughout the supply chain makes it possible to trace the product’s shelf life, verify its origin and guarantee its authenticity. This is key both for consumer safety and to avoid counterfeit or out-of-specification products, especially in sectors such as food, pharmaceuticals and cosmetics.

Do you want to reduce errors, save costs and optimize every step of your production? At United Barcode Systems we offer labeling, coding and marking solutions with maximum guarantees. We study your case and give you personalized advice.

Contact us and find out how our equipment can help you transform your supply chain.