In the industrial sector, choosing the right technology for product marking and coding is key to ensuring traceability, efficiency and regulatory compliance. Two of the most widely used technologies today are piezoelectric inkjet and thermal inkjet (TIJ). While both allow variable data to be printed in real time, they differ significantly in their operation, applications and performance. In today’s article, United Barcode Systems, specialists in providing labeling, coding and marking solutions, takes an in-depth look at their differences and helps you understand which one is best suited to your production line.

What is piezoelectric inkjet technology?

Piezoelectric inkjet technology is based on the generation of electrical impulses that deform a piezoelectric crystal, which drives the ink towards the surface to be printed. This process, highly controlled and precise, allows to obtain drops of different sizes and shapes, which results in a cleaner and more adaptable marking to different materials and finishes.

Operation and technical characteristics

Piezoelectric systems have a permanent printhead that is not replaced with each ink charge, reducing waste and long-term costs. These printheads are capable of launching droplets with micrometer precision, resulting in superior print quality, especially for small text, logos and 1D/2D barcodes.

In addition, this technology works with independent ink tanks, allowing greater control of consumption and more efficient management of the resource. The inks available are usually oil-based or UVLED, options that stand out for their durability, fast drying and environmental friendliness, as they do not contain mineral oils.

Operational advantages of Piezo Inkjet Technology

Tank with greater autonomy

One of the main advantages of inkjet equipment with piezoelectric heads is that the ink is housed in large-capacity tanks, independent of the head. This allows the equipment to run longer without intervention, reducing unnecessary stoppages and improving production flow.

Consumable changeover without stopping production

Thanks to its modular architecture, it is possible to change the ink tank without stopping the production line, which represents a significant improvement compared to technologies where the change involves stopping the entire operation.

Low cost per print

By separating ink and printhead, the costs associated with integrated consumables are eliminated. This separation allows only the necessary ink to be used, optimizing economic performance especially in continuous or high volume production.

Ideal for medium to high production

Sustained performance, coupled with lower operating costs, makes piezo inkjet systems the ideal choice for demanding industrial environments with medium to high production lines that require speed, accuracy and reliability.

What is Thermal Inkjet Technology (TIJ)?

Thermal Inkjet (TIJ) technology uses heat to generate bubbles that expel ink droplets onto the surface to be marked. It is a compact technology, based on cartridges that include both the head and the ink, which facilitates its use and maintenance, although with some limitations regarding volume and durability.

How it works and when it is used

In a TIJ system, a resistor heats the ink until it is partially vaporized, generating a bubble that forces it out through a nozzle. This system, although simple and effective, depends entirely on the cartridge, which means that with each replacement the print head is also replaced.

Because of its small size and portability, the TIJ is a popular solution for small or low-turnover production lines where continuous printing is not required and where operational simplicity is more important than cost per print or autonomy.

Lower initial investment

One of the main attractions of Thermal Inkjet (TIJ) technology is its low implementation cost. As a compact, self-contained system, with the printhead integrated directly into the ink cartridge, the need for high initial investment in complex equipment is eliminated. This makes TIJ an affordable option for companies wishing to incorporate coding systems into their lines without large outlays, making it especially useful in pilot phases, auxiliary lines or projects with limited budgets.

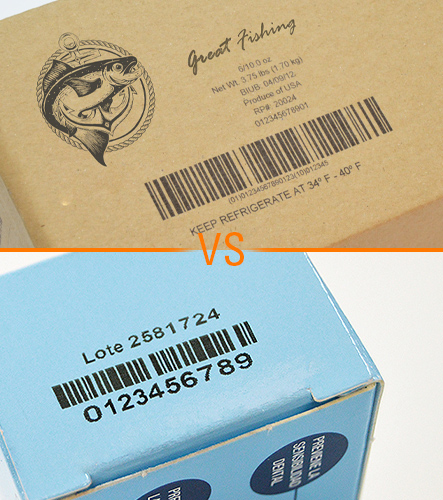

High resolution for code and date printing on small packages

TIJ technology stands out for its ability to print at high resolutions, reaching up to 600 dpi, ensuring clarity and sharpness in the marking of critical elements such as expiration dates, batch numbers or QR codes. This precision makes it especially recommended for printing on small packages, where legibility is essential to comply with traceability, product identification and scannability regulations at logistic or sales control points.

Portability and ease of maintenance

Thanks to their compact, modular design, TIJ systems can be easily adapted to different spaces on the production line, even in locations where space is at a premium. At the same time, maintenance is minimal: by incorporating the printhead into the cartridge itself, a new printhead is also installed each time the ink is replaced, eliminating the need for frequent cleaning or technical adjustments. This not only simplifies operation, but also reduces downtime and improves operational efficiency.

Useful on lines with low to medium line turnover

By its nature, the TIJ is especially effective in low to medium-demand production lines where a continuous high-performance printing system is not required. Its ease of installation, low maintenance and cost per use make it ideal for operations where cycle times are not as intensive and where operational flexibility is more valued than long run time or high print speed.

Comparison: Piezo Inkjet Technology vs. Thermal Inkjet Technology

Both technologies offer effective solutions for industrial coding, but respond to different needs. While Piezo Inkjet technology excels in high production environments, with complex graphic demands and a need for durable and sustainable printing, the TIJ system is positioned as a practical option for simpler or lower volume lines.

Inkjet Piezo technology allows greater autonomy, precision and versatility in terms of formats and ink types. In addition, TIJ technology offers fast installation and minimal maintenance, which can be advantageous in temporary applications, low-turnover environments or decentralized production.

In addition to the initial investment, the cost of the consumables is a key factor in the decision. In this sense, one of the advantages of TIJ becomes a disadvantage compared to piezoelectric printheads: the consumable. In TIJ printers this is a cartridge, a small ink tank that incorporates a printhead. This has an impact on the price per liter of consumable: for every 35ml of ink, the cost of a printhead must be added. On the other hand, piezoelectric inkjet printers have their own printhead (more technological and durable), which has a greater impact on the initial investment, but reduces the price of the consumable, since this is only the ink, without other attributable costs.

| Feature |

Piezoelectric Inkjet (APLINK LCXe) |

Thermal Inkjet (TIJ) |

| Head |

Fixed, precise droplet control |

Integrated in cartridge |

| Ink Type |

Mineral-free oil/ UVLED |

Solvents / specific inks |

| Autonomy |

High (independent and refillable tank) |

Limited to cartridge size |

| Consumable change |

Without stopping production |

Requires complete cartridge replacement |

| Cost per print |

Low |

Higher |

| Initial investment |

Higher |

Lower |

| Ideal for… |

Medium/high production, graphics printing |

Low/medium production, text printing |

| Sustainability |

Alto (tintas ecológicas, menos residuos) |

Low (continuous waste generation) |

| Flexibility in formats |

High: texts, logos, pictograms, codes |

Limited: texts, simple codes |

Which technology or equipment to choose according to your production line?

The choice between the two technologies must consider several factors: production volume, package surface, graphic needs, line speed and sustainability. For lines with high workloads, where efficiency and reduced operating costs are key, piezoelectric inkjet technology is a robust and cost-effective solution. It is also ideal if complex text, logos or symbols need to be printed with stable resolution.

On the other hand, on simpler lines, with reduced space or less demanding printing requirements, TIJ systems are a competitive alternative, especially when ease of use, portability and fast start-up are priorities.

APLINK LCXe: Performance, Sustainability and Versatility

The APLINK LCXe is a high-resolution inkjet printer equipped with a piezoelectric printhead, designed to offer direct coding with maximum cost savings. Thanks to its ability to print messages up to 36 mm in height and a resolution of up to 360 x 180 dpi, it guarantees perfect readability of text, images, logos and 1D and 2D codes compatible with GS1 standards (GTIN13, GTIN14, GS1-128, Datamatrix, QR, etc.). This accuracy remains constant even on demanding production lines and with both porous and non-porous surfaces.

With speeds of up to 50 m/min and print rates of up to 10 prints per second, the APLINK LCXe is an effective solution for companies looking for sharp, adaptable printing without compromising energy efficiency. Thanks to its Plug and Print technology, it is ready to run at start-up and requires no daily maintenance, just an annual service. It uses environmentally friendly inks – mineral-free oil for porous materials or low-migration UVLED ink for non-porous materials – positioning it as an eco-friendly and sustainable solution. In addition, its integrated 7” HMI touch screen and its connectivity with external databases through UBS LABMAN allow total control of the marking process, facilitating its integration into any automated line.

Two technologies, one tailor-made solution

The reality is that there is no single universal solution, but rather a technology suited to each production need. While piezoelectric inkjet technology represents the best option for demanding industrial processes with high print volumes, low operating costs and the need for graphic versatility, TIJ technology offers a simple and efficient approach for lower volume companies or facilities with technical limitations.

At United Barcode Systems, we understand that every customer has unique needs. That’s why we offer both technologies, along with a team of experts to help you identify the best solution for your production line. Whether it’s direct printing or spot coding, we will advise you to achieve the highest performance with maximum reliability.