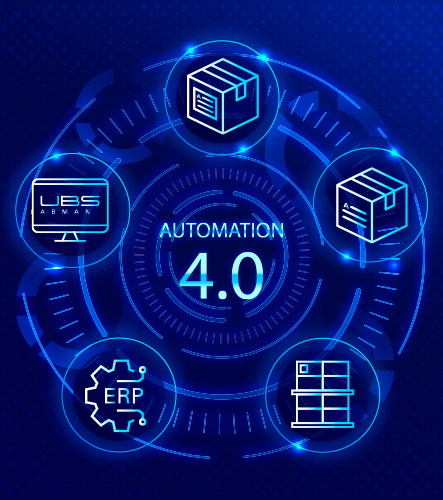

Industrial automation has evolved from being a trend to becoming a necessity for any company aiming to optimize processes, reduce errors, and stay competitive in an increasingly digital environment. However, moving toward Automation 4.0 doesn’t have to mean stopping production or carrying out a drastic transformation from day one.

With a well-planned strategy and the right tools, it’s possible to gradually integrate equipment, software, and traceability systems —ensuring a smooth transition toward a more efficient and intelligent production line.

1. Analyze the Starting Point: Diagnosing the Production Line

The first step in automating an industrial process is to assess the current workflow —identifying repetitive tasks, bottlenecks, and points where human errors or time losses occur.

This phase helps determine which areas can benefit first from automation. For instance, in many plants, labeling and coding are often the ideal processes to start with, as they involve repetitive and traceability-critical operations.

A technical audit also helps define the connectivity and compatibility requirements with existing systems such as ERP or WMS, ensuring seamless integration.

2. Start with Modular Processes: Gradual and Flexible Automation

Automation doesn’t have to be implemented all at once. A gradual approach allows companies to automate the most critical or high-impact operations first —without interrupting production.

One of the most effective strategies is to incorporate equipment that can be easily integrated into existing lines. For example, the APL 80S by United Barcode Systems, designed for automatic pallet labeling, enables automation of the final stage of the logistics process without modifying current infrastructure. Its precise application system and ability to print and apply labels in multiple pallet positions ensure a continuous workflow.

Likewise, the APL 35S by United Barcode Systems, ideal for box labeling, offers a compact, versatile solution easily integrated into operational lines. By automating secondary labeling, companies reduce handling time and identification errors —improving efficiency immediately.

These modular systems allow automation to progress step by step, adapting to each company’s production pace and operational needs.

3. Integrate Direct Printing for Greater Agility

Once labeling phases are automated, the next natural step is to incorporate direct printing on packaging. The APLINK HRX Series stands out for its high-resolution inkjet technology, capable of printing codes, logos, and variable data directly onto boxes, bags, or packs.

Its robust design and ability to operate at high speeds make it the perfect choice for companies seeking to optimize coding without using labels. Moreover, since it requires no direct contact with the product, maintenance is minimal and production flow remains constant.

Direct printing not only boosts efficiency but also helps reduce costs associated with label and material consumption —providing a competitive advantage in both sustainability and profitability.

4. Connect Hardware and Software: The Foundation of Smart Automation

True Industry 4.0 automation happens when hardware communicates seamlessly with management software. Labeling and coding systems must integrate with platforms that control production, inventory, and logistics.

In this regard, UBS LABMAN acts as a centralized labeling and coding management software, capable of connecting printing and labeling equipment with ERP or WMS systems. This ensures that all production and traceability data flow automatically, eliminating manual errors and guaranteeing full synchronization between the factory floor and business management.

Meanwhile, UBS DESIGNER allows users to easily create and manage label and message designs, adapting to each customer’s requirements, regulations, or product formats. Together, these software solutions —combined with UBS equipment— create a complete ecosystem, ready for smart automation and a connected industry.

5. Training and Technical Support: Keys to a Successful Transition

Implementing automation solutions requires more than just technology —it also needs expert guidance and training. Having a professional team to configure, monitor, and optimize integration ensures that new systems work from day one without affecting production continuity.

At United Barcode Systems, we provide personalized consulting, technical support, and preventive maintenance to guarantee that the transition to automation is safe, scalable, and adapted to each client’s environment.

This collaborative approach allows companies to progressively adapt to new processes, maximizing the benefits of automation without operational risks.

Automate Your Production Without Pauses or Risks

Automation 4.0 is not a distant goal —it’s a path that can be taken step by step. With modular and scalable solutions such as the APL 80S by United Barcode Systems, APL 35S by United Barcode Systems, and APLINK HRX Series, along with UBS LABMAN and UBS DESIGNER software, any company can begin its digital transformation without stopping production.

Automating means gaining efficiency, traceability, and control —but also flexibility and responsiveness. At United Barcode Systems, we help industries digitize their labeling, coding, and marking processes with integrated solutions tailored to their pace and needs.

Take the next step toward smart automation and discover how to optimize your production without interruptions. Contact our team and start your transition toward a more connected, efficient, and future-ready industry.