Ink temperature and viscosity control Systems for perfect drop, together with instant curing Innovative technology, guaranty constantly low ink consumption and perfect print out quality.

- Applications

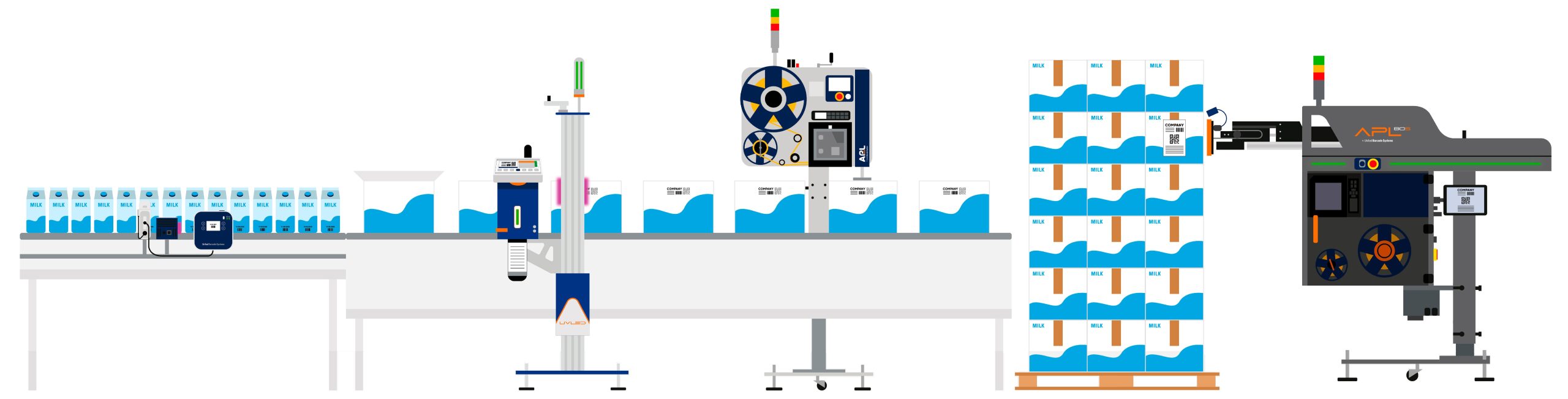

- Automatic identification solutions for any production line

- End-of-line pallet labeling

- automatic, real-time labeling on secondary packaging

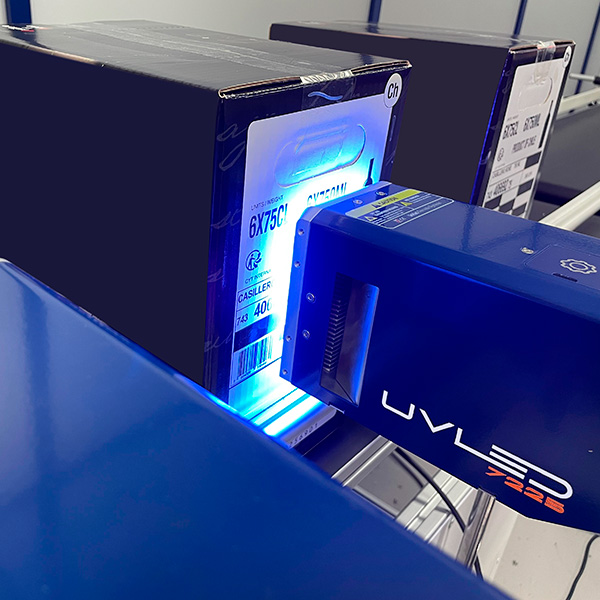

- Direct coding and printing on boxes

- Direct printing using UVLED curing system

- Marking and Coding of Primary Product: TIJ

- Printing and marking of pallets with inkjet printers

- Product

- Industries

- YOU KNOW WHAT

- Company